Tungsten Carbide HRC55 4 Flute Flat End Mills For Cutting Tools

Advantages of Tungsten Carbide Flat End Mills

1.Strong wear resistance

Tool wear and friction heat are behind the scenes of workpiece scrapping

We use AltiSiN(nitrogen silicon titanium aluminum) multilayer composite nanostructure cotating

Effectively reduce the generation of friction heat and tool wear.

2.Full grinding edge

Full edge grinding, sharp cutting.

High process reliability and higher production efficiency can be achieved

Cutting parameters are much higher than the common products on the market

The life of cutting edge has been improved a lot

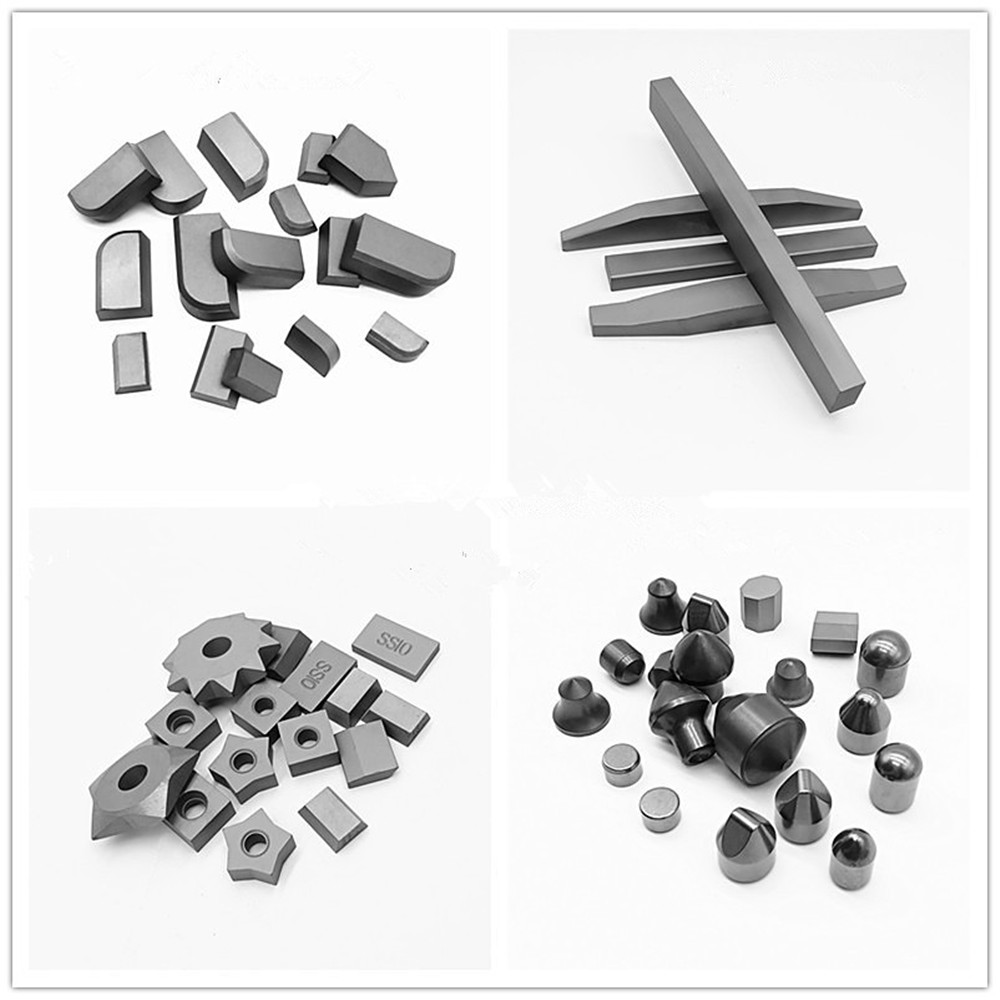

3.High quality raw materials

Selected high quality wear-resistant tungsten carbide materials, 0.4-0.6 micron ultra-fine particles

The particle size distribution is concentrated and the wear resistance is excellent.

It can greatly improve the tool life

Product Description of Solid Coated Carbide Flat End Mills

Product name

| Tungsten Carbide HRC55 4 Flute Flat End Mills

|

Material

| 100% Virgin tungsten carbide

|

Grade

| YL10.2, YG6X, YG8, YG10, YG15, YG20, etc.

|

Types

| carbide square end mill, carbide flat end mills, solid Carbide Ball Nose End Mill, 2 fluts end mill, 4 flutes end mill, corn end mills, left-handed corn end mills, taper ball knife, composite end mill, non-standard custom end mill, etc.

|

Dimension

| OEM customization available, diameter is from 0.2mm to 25mm,total length is from 50mm to 200mm, include inch size end mill, the number of Flute is 4F, 5F, 6F, 8F and the logo could be customized.

|

Application

| For processing of stainless steel, carbon steel, alloy steel, cast steel, tooling steel, mould steel, heat-treatment steel, Aluminum alloy steel, cast iron,Non-ferrous alloy, metal , plastic and other materials

|

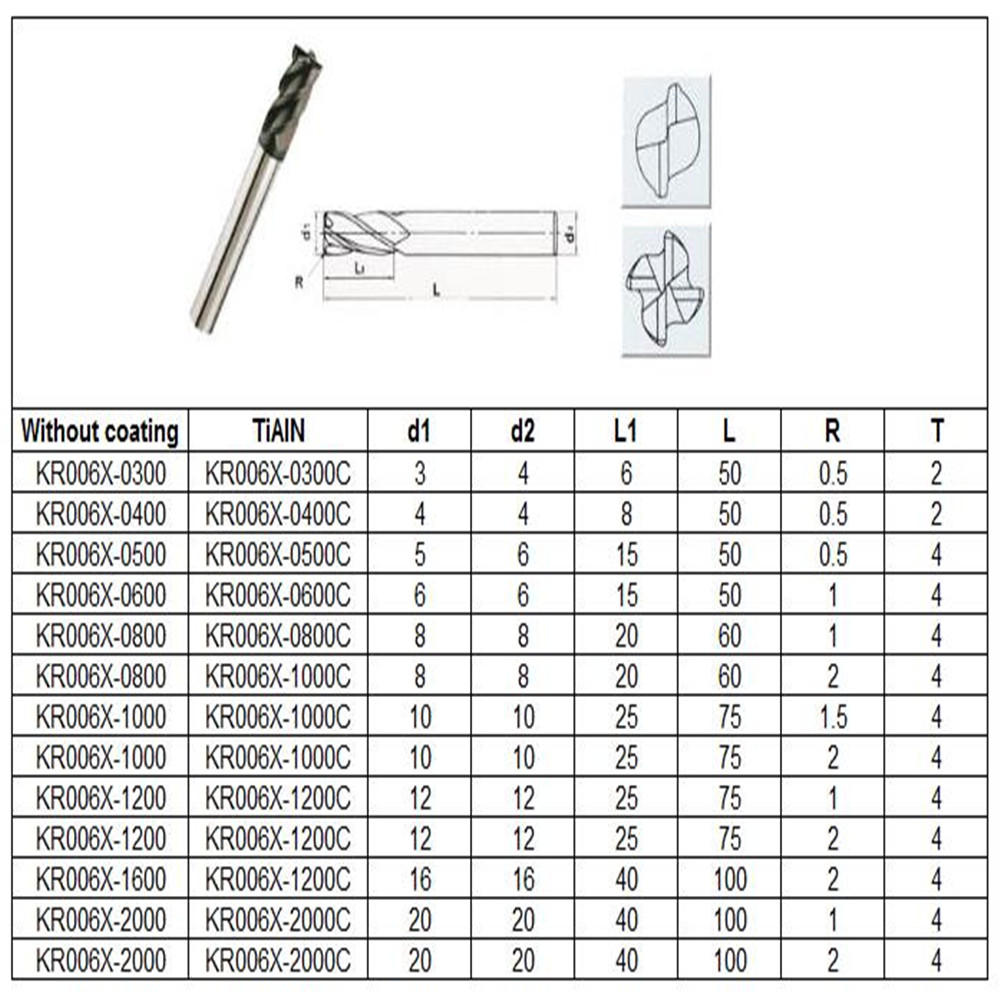

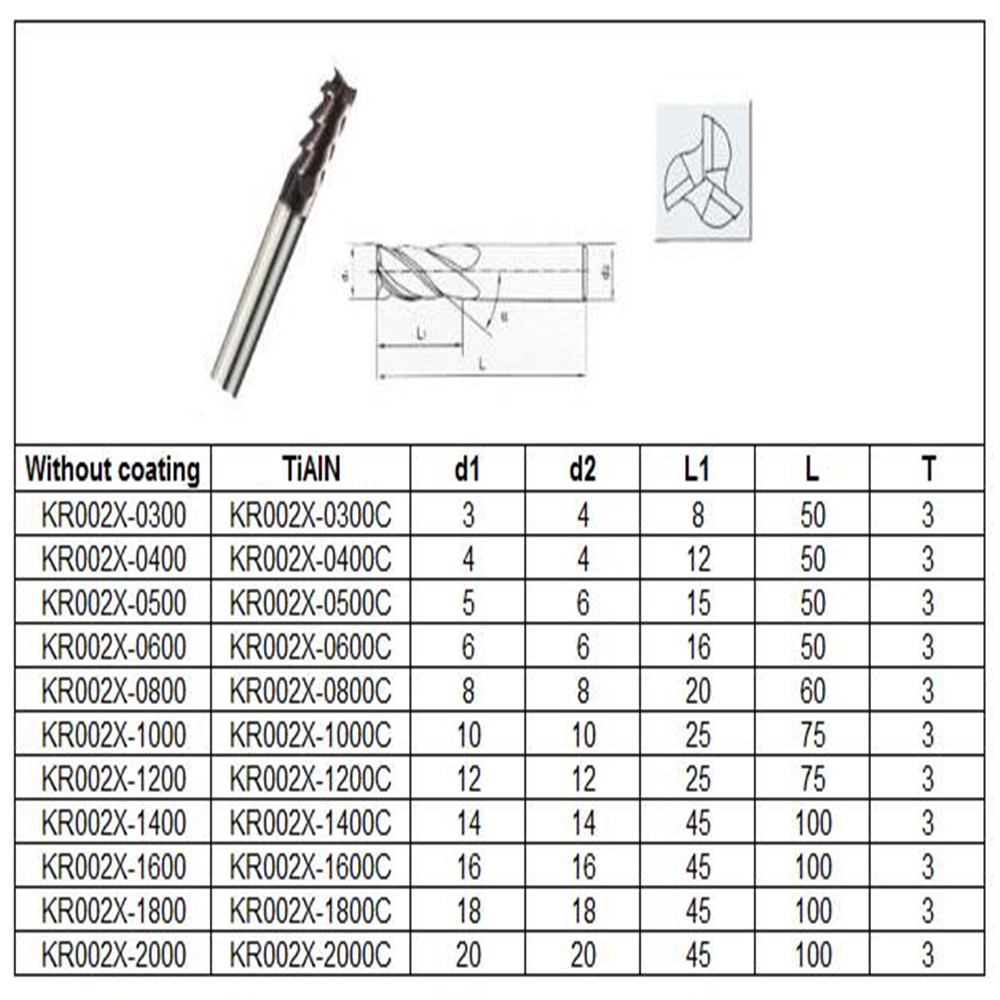

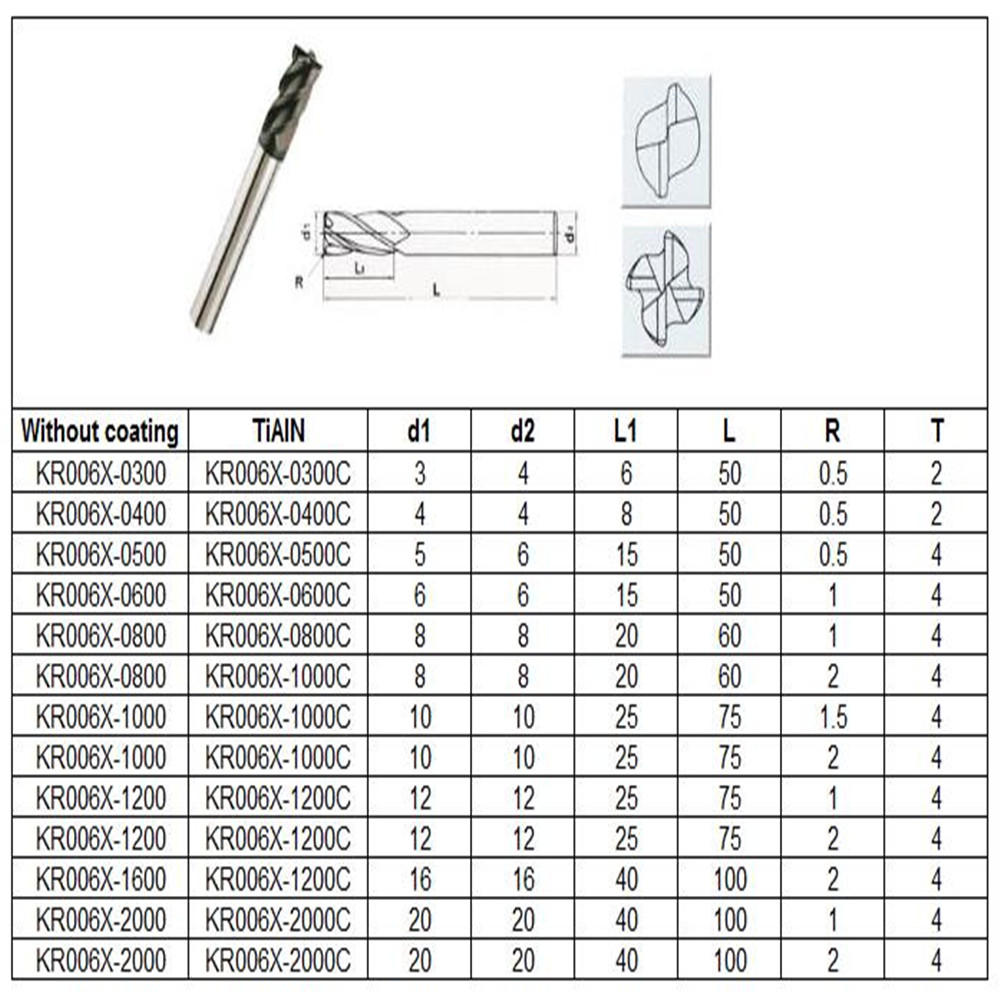

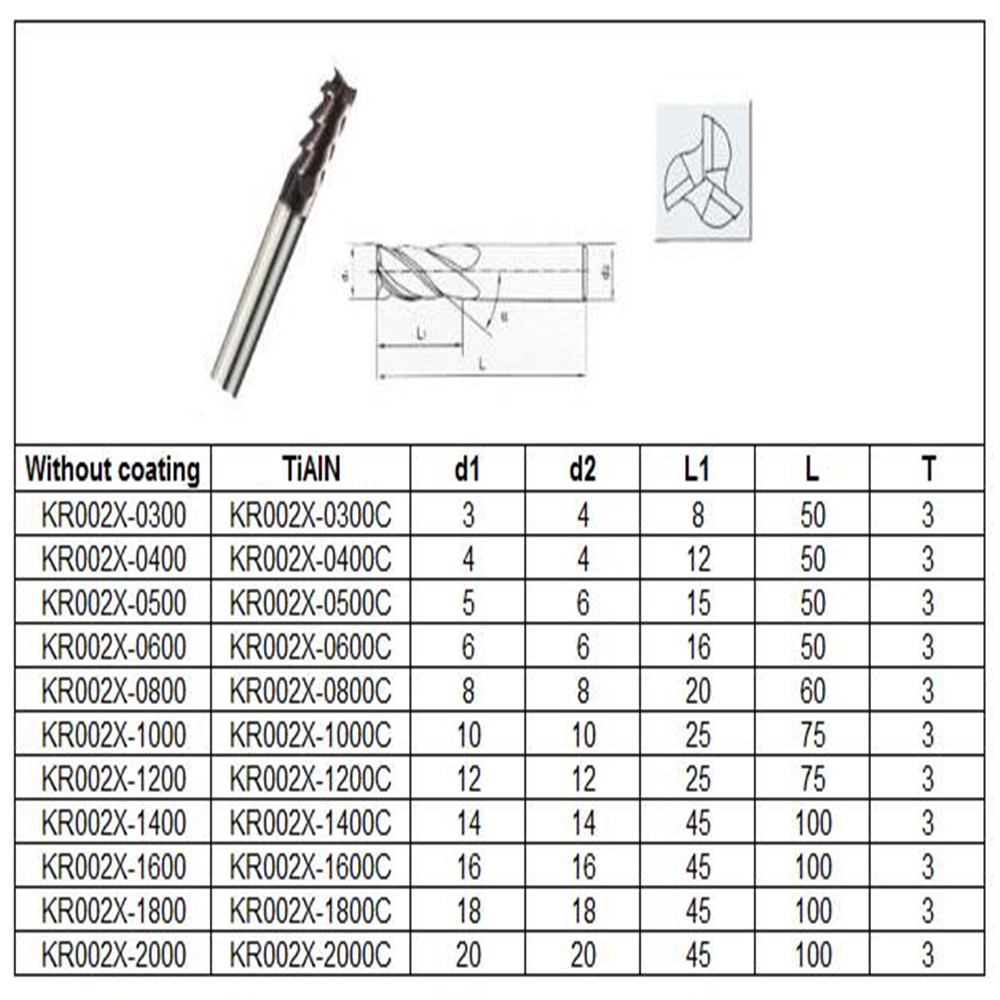

Specification of Tungsten Carbide Solid End Mills

Standard dimension of end mills(=flute dia.*handle dia. *total length)

Zhuzhou produce a lof of types of cemented carbide end mills, square end mills, carbide ball nose

end mills, customized end mills,etc. Just list some dimensions FYI. Pls kindly note that customized\

end mills are also available.

Application of tungsten carbide end mills

Tungsten carbide is a hard material used extensively as cutting tool material, as well as other

industrial applications. It consists of fine particles of carbide cemented into a composite by a

binder metal. End mills are made from tungsten carbide which are used for processing of

stainless steel, cast iron, alumnium, cooper, graphite, plastic,composite material,titanium,

nickel, heat-resistant steel, non-alloyed steel, low-alloyed steel<24HRC, High-alloyed

steel<30HRC,Hardened steel 30-38HRC, 38-48HRC, 56-68HRC, etc.

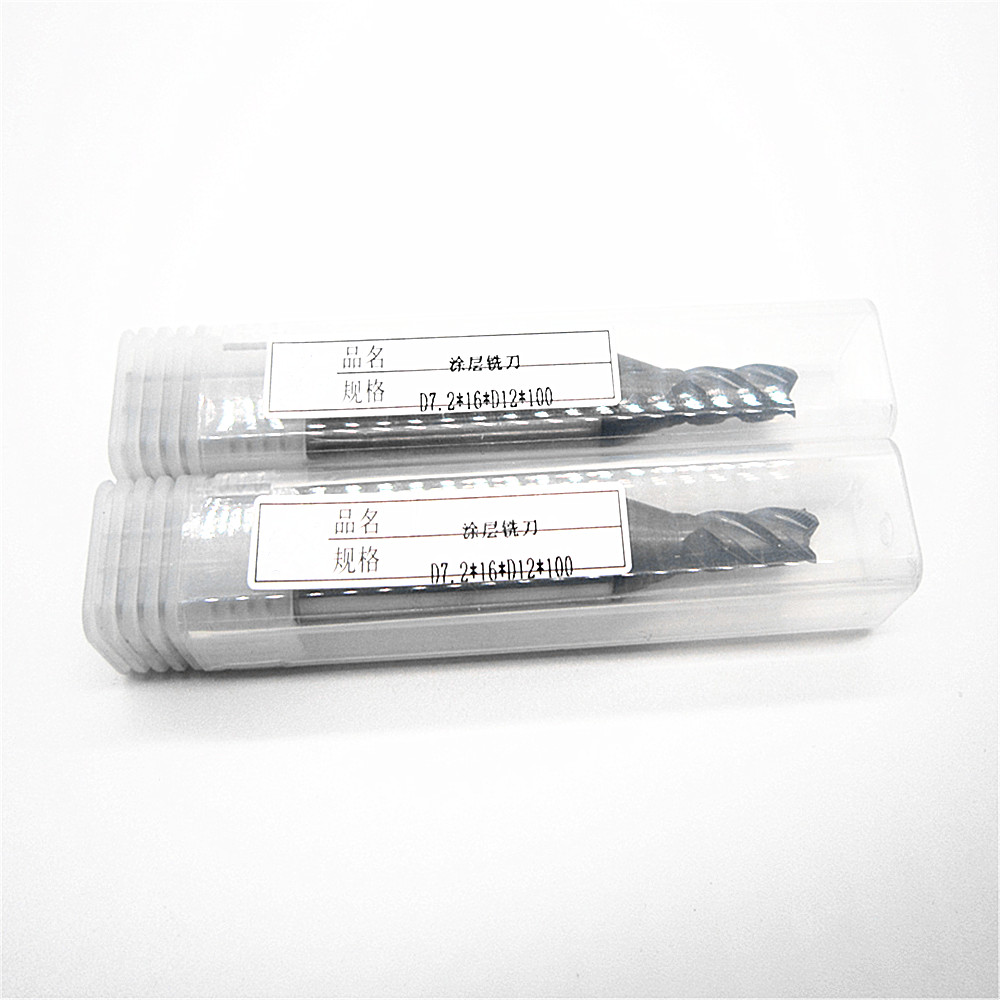

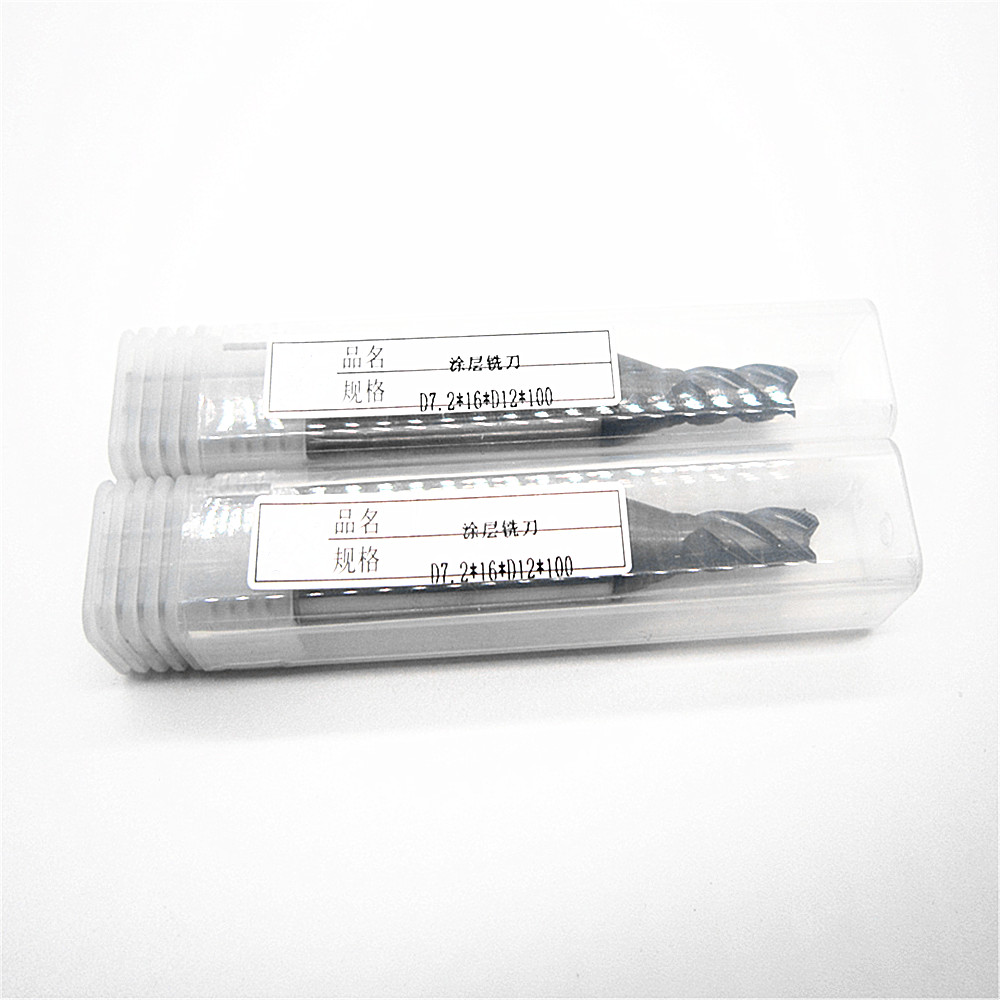

Package of tungsten carbide endmills with coating

Standard package of Carbide Rod: first wrap the Solid Carbide Rod in paper, then put them into the paper box, finally put them into the carton. We also can customize the package as per your request.

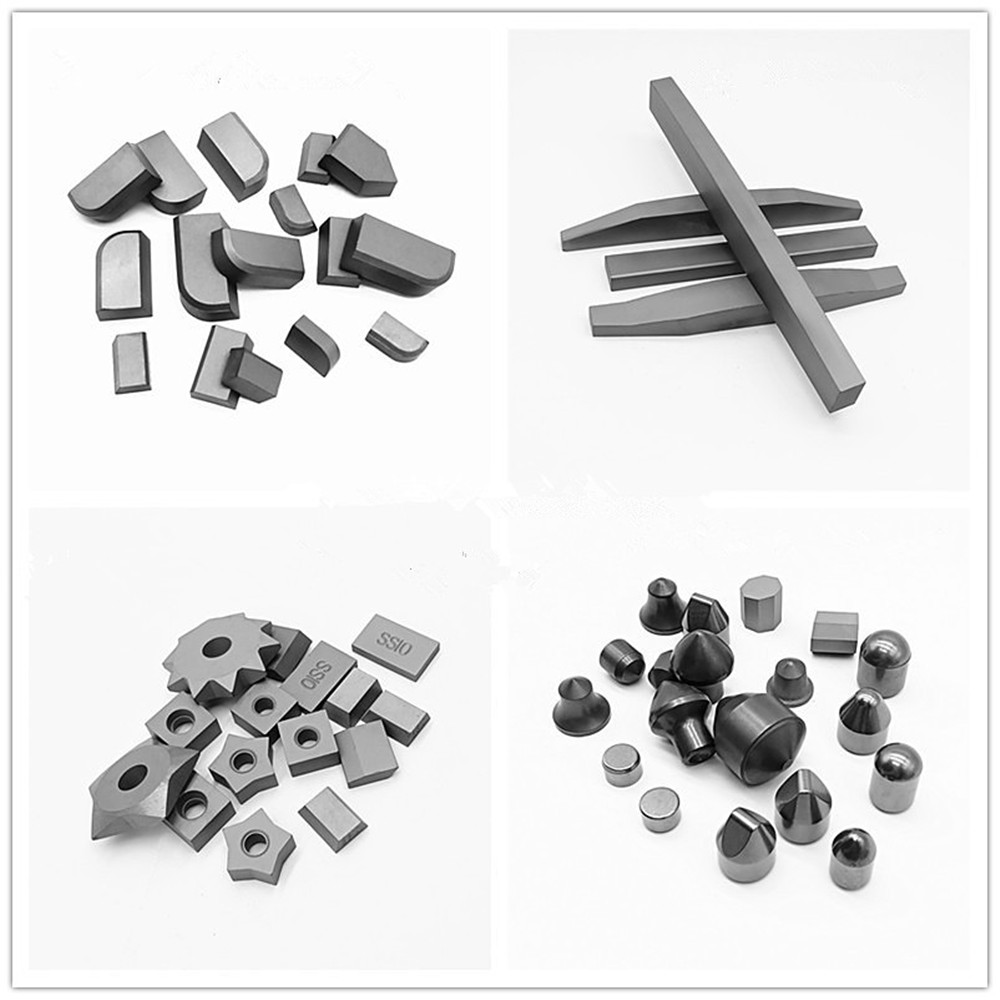

Main products from Zhuzhou Kerui Cemented Carbide